Specifications

This factory has been founded on a 2,500 m2 ground in Kaveh industrial city of Saveh province and the machinery and the equipment are from England, Italy, China and Iran.

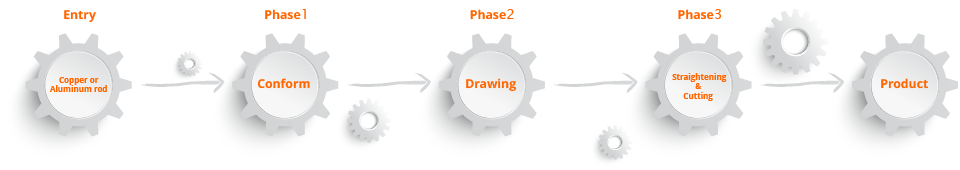

Production process

Entry:

The raw material is obtained from wire factory in varied dimensions.

Phase 1: Conform (Made in England)

First the copper or aluminum wires are heated up to 650 C° by friction and then according to the type of the molds different sections are produced and wound around wooden spools.

Phase 2: Drawing (Made in Italy)

The coils produced in phase 1 are size-drawn in drawing machine and then are packed to be delivered to the customer.

Phase 3: straightening and cutting (Made in China)

If the customer orders Busbar, the size-drawn coils are straightened in this section and then are cut according to the order.